Possessing a comprehensive understanding of the daily operations within the stonemasonry profession provides prospective individuals with a clear perspective on the expectations and preparations necessary for embarking on a career in this field. Stonemasonry offers a captivating avenue for employment; however, it also presents distinct challenges and considerations that must be meticulously evaluated.

In this blog post, we will delve deeper into the various tasks and activities that are commonplace in the daily responsibilities and life of a stonemason, offering insights into the intricacies of this ancient and respected craft.

Key Takeaways

- Stonemasonry is a blend of art and craftsmanship, demanding not only physical strength but also precision, technical skill, and an understanding of stone properties to transform raw materials into architectural elements.

- Daily tasks for stonemasons include preparing the worksite and materials, taking precise measurements, and using advanced technology for planning and execution, emphasizing the importance of meticulous preparation in achieving quality workmanship.

- The process of cutting, shaping, and polishing stone showcases the core of stonemasonry, where raw stone is meticulously crafted into functional and aesthetic pieces, requiring a balance of power tools for rough shaping and hand tools for detailed finishes.

- The fabrication and installation of custom stone products highlight the custom design capabilities and technical precision of stonemasons, underscoring the importance of client collaboration in bringing visions to life.

- Safety and continuous learning are paramount in stonemasonry, with a focus on implementing stringent safety measures, ongoing training in the latest protocols, and the adoption of ergonomic practices to safeguard stonemasons’ health and enhance their craftsmanship.

Life of a Stonemason: A Day-to-Day Tasks

Preparing Worksite and Materials

The aspect of preparing the worksite and materials is a critical part of a stonemason’s daily routine, involving several key steps that lay the foundation for a successful workday.

1. Arrival and Assessment of the Worksite

Upon arriving at the job site, the first step for stonemasons is to assess the workspace. This involves checking the area for any potential safety hazards, understanding the layout, and determining the best locations for their tools and machinery.

This time is also used to coordinate with other workers on-site, such as carpenters, electricians, and site managers, to ensure a smooth workflow and to address any potential conflicts in workspace usage.

2. Setting Up Tools and Machinery

After assessing the site, the stonemasons proceed to unload and set up their equipment. This includes the basic hand and power tools for cutting and shaping stone, such as:

Hand Tools

- Hammers

- Points

- Chisels

- Tracers

- Splitting Wedges

Power Tools

- Saws

- Polishers

- Grinders

The setup process is crucial for ensuring that tools are easily accessible and that machinery is positioned safely and efficiently, minimizing unnecessary movement during the workday.

3. Selecting and Preparing Stone Materials

Selecting the suitable stone materials for a project is a task that requires a deep understanding of the properties of different types of stone, such as their color, grain, hardness, and how they respond to various finishing techniques.

Once the stone has been selected, stonemasons begin preparing the materials for installation.

Measuring and Planning

The measuring and planning phase is a crucial aspect of a stonemason’s daily activities, demanding high precision, technical skill, and analytical thinking.

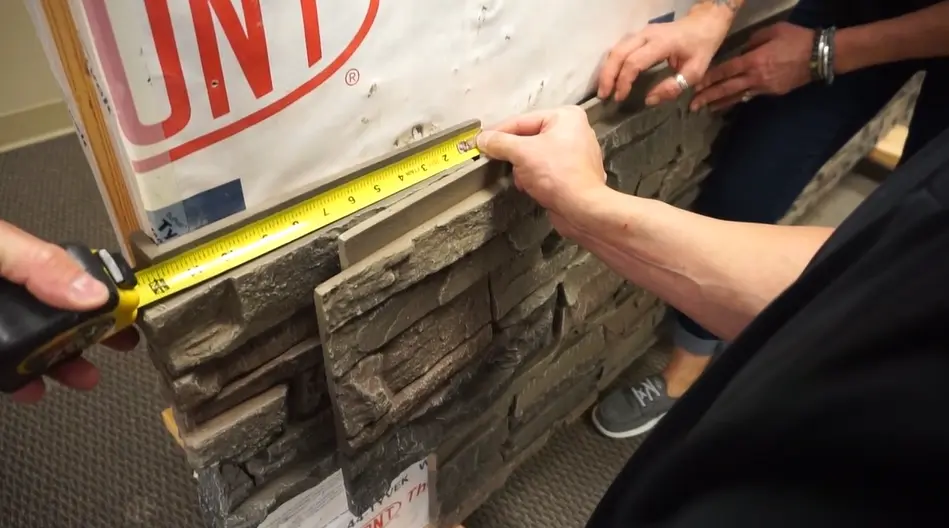

1. Taking Precise Measurements

Upon arrival at a job site, the immediate task is to take precise measurements of the areas where stone finishes or structures will be installed. This step is vital for ensuring that the stone pieces fit perfectly in their designated spaces, aligning with the overall design and functional requirements of the project.

2. Using the Latest Technology

To achieve the highest level of accuracy, stonemasons utilize the latest technology in measurement and design. This includes digital measuring tools, laser levels, and CAD (Computer-Aided Design) software that allow precise calculations and adjustments.

3. Reading and Interpreting Plans and Drawings

A significant part of the planning process involves carefully reading and interpreting architectural plans, drawings, and designs. This skill is crucial for understanding the architect’s or designer’s vision and ensuring that the stonework complements the overall structure and aesthetic of the project.

4. Collaboration and Communication

Effective communication with architects, designers, contractors, and clients is essential during the measuring and planning phase. Stonemasons often engage in discussions to clarify project details, confirm design choices, and coordinate with other tradespeople to seamlessly integrate the stonework with different construction or renovation project elements.

Image Source: westerninterlock.com

Cutting, Shaping, and Polishing Stone

The cutting, shaping, and polishing of stone are central to the craft of stonemasonry, embodying the transformation of raw, natural materials into functional and aesthetic architectural elements.

1. Cutting Stone

The process begins with cutting the stone to rough dimensions that approximate the final size needed for the project. This is often done using heavy-duty machinery like diamond-tipped saws, which can handle the hardness of stones such as granite, marble, limestone, and sandstone.

Precision in cutting is crucial to minimize waste and ensure that the piece of stone can be further refined and shaped to closely match the project’s specifications.

2. Shaping Stone

After cutting, the stone is shaped to its final form. This step requires a combination of power and hand tools, depending on the complexity of the design and the level of detail needed.

Power tools, such as:

- angle grinders

- pneumatic hammers

are used for removing larger sections of material and shaping the stone’s general outline.

Hand tools, including:

- Chisels

- Files

- Rasps

are then employed for finer work and detailing, allowing the stonemason to achieve the precise contours and textures desired.

3. Polishing Stone

Polishing is the final step in the stone preparation process, enhancing the stone’s natural beauty and creating the desired finish, whether:

- Glossy

- Matte

- Textured

The polishing process involves smoothing the stone surface with progressively finer abrasives, depending on the type of stone and the finish required. These can range from coarse diamond pads to very fine polishing powders.

Image Source: vimeo.com

Custom Stone Product Fabrication and Installation

The fabrication and installation of custom stone products stand as a testament to the blend of technical precision, artistic creativity, and client collaboration inherent in the stonemason’s profession.

1. Custom Design and Fabrication

The process begins with understanding the client’s vision for custom-designed elements like kitchen countertops, fireplace surrounds, pathways, or pool surroundings. This involves detailed discussions to capture the client’s desires regarding stone type, color, finish, and overall design.

Stonemasons then measure the space where the stone will be installed precisely. Accurate measurements are crucial for custom projects where even a small error can lead to significant issues with the fit and finish of the product.

2. Installation

Installing custom stone products requires careful planning and execution. Stonemasons must transport the fabricated stone pieces to the site without damaging them, which often involves special packaging and handling techniques.

The installation process on-site varies depending on the type of project. For example, kitchen countertops might need to be glued and sealed to cabinets, while outdoor pathways require a stable foundation for the stone slabs.

3. Client and Site Manager Liaison

Communication with clients and site managers is an ongoing part of the process. Stonemasons provide updates on the project’s progress, address any concerns, and make adjustments as requested to meet or exceed expectations.

Image Source: https://www.artofmarble.com.au/post/natural-stone-care-maintenance

Maintenance and Repair

Maintaining and repairing existing stonework are critical aspects of a stonemason’s responsibilities, requiring unique skills that combine historical knowledge, technical expertise, and a delicate touch.

1. Conducting Restoration and Repair Works

Restoration and repair work involves a detailed assessment of the stonework to identify damage, wear, or structural issues that have occurred over time. This can include everything from erosion, cracking, and chipping to staining and biological growth, such as moss or lichen.

2. Choice of Restoration Techniques

The choice of materials and methods for restoration work is crucial. Stonemasons must select materials compatible with the original stone in terms of composition, color, and durability to ensure a seamless repair that maintains the structure’s historical and aesthetic integrity.

Safety and Challenges

The implementation of a ban on engineered stone benchtops by the leading manufacturer, Caesarstone, has underscored the critical issue of occupational safety. This action was primarily motivated by the heightened concern for workers’ health, particularly regarding the risk of silicosis—a lung disease attributed to the inhalation of dust particles from stone materials.

Consequently, this situation has necessitated a stronger focus on adapting workplace practices and challenges to safeguard the health and well-being of stonemasons. Ensuring the safety of these workers is not only a matter of regulatory compliance but also a crucial component of enabling them to deliver their highest quality work without compromising their health.

1. Implementation and Vigilance

Stonemasons must implement stringent safety measures due to the risks associated with handling heavy materials and operating dangerous machinery. This includes wearing personal protective equipment (PPE) such as:

- Safety glasses to protect against flying chips of stone

- Gloves for handling sharp or rough surfaces

- Ear protection to guard against long-term hearing loss from machinery noise

- Dust masks or respirators to prevent inhalation of harmful stone dust.

2. Training and Awareness

Continual training on the latest safety protocols and awareness of potential hazards are critical. Stonemasons must stay informed about the best practices for operating equipment and handling materials safely. This ongoing education helps in minimizing the risk of accidents and injuries.

3. Equipment Maintenance

Regular maintenance and checks of machinery and tools ensure they are safe to use. Faulty equipment can be a significant safety risk, so stonemasons must inspect their tools regularly and adapt their maintenance routines to the demands of each project.

4. Physical Fitness and Endurance

The job requires stonemasons to be in good physical condition as they often lift heavy stones, stand for extended periods, and perform repetitive motions. Developing strength, stamina, and proper lifting techniques is essential to handle these physical demands.

5. Ergonomic Practices

Adapting ergonomic practices into their daily routines helps stonemasons minimize strain and prevent injuries. This includes using equipment that reduces the physical toll on their bodies, such as hoists or forklifts for moving large stones and adopting positions that reduce back strain during carving or shaping tasks.

Are you a job seeker looking for your next big opportunity? Click below to see how we can assist you in finding the perfect role.

Conclusion

The daily profession of stonemasonry is a complex and demanding craft that requires a unique blend of physical strength, precision, artistic sensibility, and technical knowledge. From the meticulous preparation of the worksite and materials to the detailed processes of cutting, shaping, and polishing stone, stonemasons embody a dedication to their craft.

At Dayjob Recruitment, we recognize the exceptional skill set and commitment required in the stonemasonry field and are dedicated to matching the industry with the best talent available. Our rigorous selection process ensures that both job seekers and employers benefit from a perfect fit that meets the high standards of craftsmanship and professionalism in stonemasonry.

Check our latest Stonemason jobs in Melbourne here.

Check our latest Stonemason jobs in Sydney here.

Whether you are a job seeker aiming to carve your path in the stonemasonry profession or an employer seeking to enhance your workforce with top-tier talent, Dayjob Recruitment is your partner in achieving excellence. Contact us today to explore how we can help you meet your stonemasonry career or staffing needs.

Is this the role you’ve been waiting for?

FAQs

What are the career advancement opportunities for a stonemason?

Career advancement opportunities for stonemasons include becoming a site supervisor or project manager, specializing in areas like historical restoration or custom stone design, or starting their own stonemasonry business.

Experienced stonemasons may also transition into teaching positions in vocational schools or offer workshops and training programs to apprentice stonemasons.

What educational background is required to start a career in stonemasonry?

While formal education is not always required, many stonemasons start their careers with vocational training or an apprenticeship program that combines classroom instruction with on-the-job training.

Courses may cover topics such as basic construction, stone properties, cutting and shaping techniques, and safety protocols. Some may pursue further education in related fields such as architecture or construction management to enhance their skills and career prospects.

How does technology impact the field of stonemasonry?

Technology has significantly impacted stonemasonry, making processes more efficient and precise. The use of CAD software for design and planning, CNC machines for cutting and shaping stone, and digital measurement tools for accuracy are now commonplace.

These technological advancements allow stonemasons to undertake complex projects with greater precision, improve safety standards, and reduce the physical strain of manual labor.

What is the role of a stonemason?

A stonemason’s role involves repairing old buildings and monuments, creating and fitting stonework like window frames and archways, dressing stone, building walls, and working with materials such as slate, sandstone, limestone, marble, and granite. They interpret technical drawings, collaborate with historians and conservationists, and engage in creative problem-solving.

What skills does a stonemason have?

Stonemasons possess skills in building and construction, using their initiative, showing persistence and determination, and paying excellent attention to detail. They are proficient in interpreting blueprints/drawings, cutting and shaping stone, and installing stone components with precision.

What is the use of stone masonry?

Stone masonry is used in the construction of buildings, structures, and sculptures, combining both functional and aesthetic purposes. It involves creating durable structures and works of art from stone that are meant to stand the test of time, contributing significantly to the preservation of historic buildings and landmarks.

What are some facts about Stonemasons?

Stonemasons work in various specializations such as banker masons, fixer masons, memorial masons, carver masons, restoration and conservation masons, and dry stone wallers. They use a mix of traditional skills and modern technology, including heavy machinery and hand tools, to cut, shape, and install stone. Their work requires physical strength, stamina, and a deep understanding of stone properties.

Is Stonemason a good job?

Being a stonemason can be a rewarding career for those interested in combining artistic sensibility with physical work and technical knowledge. Stonemasons have the satisfaction of creating lasting structures and works of art. The career offers opportunities for specialization, self-employment, and involvement in historical preservation. The job may offer a sense of accomplishment from crafting enduring stone works, though it also demands significant physical labor and safety precautions.

Do you know the perfect candidate for the job? Refer and start earning today!